Yin and Yang - Behind the scenes: crafting Jasmine Tea (Part2)

When tea is stored somewhere wet or pungent, you may notice that over time the tea absorbed the smell from its surrounding.

Tea has excellent aroma absorption characteristics, and fresh flowers like jasmine release strong floral scent. These two opposite characters complement each other beautifully, when it comes to the scenting of tea.

When it comes to traditional scenting of jasmine tea, there are around eight individual steps involved - 1. Preparation of tea base 2. sorting of jasmine flowers 3. Weighing of jasmine flowers 4. Scenting 5. Ventilate 6. Removal of flowers 7. Roasting/dry 8. Final scenting

Apart of from the preparation steps 1-3, we count Step 4 to 7 as one scenting cycle.

Trivia: How to designate the grade of jasmine tea? In judging the quality of a jasmine tea, we are not just looking for the aroma strength - this can be enhanced relatively easily with repeated mechanical processing or substitutional/artificial scent. The resulting jasmine tea from these non-natural scenting has sometimes overpowering scent that is flat and dull.. One important sensory test is whether there is sufficient liveliness and depth to the aroma, which are consistent with skilful craft and quality of ingredients used.

Step 1: Preparation of tea base

What happens in scenting is a physical transfer of natural jasmine oil from the fresh flowers onto the tea. And so the scenting process involves mixing the two ingredients together and creating an efficient transfer contact surface.

The tea base to which the aroma is to be absorbed needs to be sufficiently dry for the adsorption to happen.

So, depending on the temperature and humidity of the day, combined with conditions of tea base, the craftsmen may first roast the tea base quickly as a preparation for scenting.

Step 2: Sorting of jasmine flowers

Freshly picked unopened jasmine flowers during the day slowly open in the night. At night, when flowers open to around 50-60% of fully blossomed state, they are ready for scenting.

Jasmine flowers are very delicate. When they are collected in bamboo baskets, flowers need to be constantly ventilated - done by hand lifting flowers in the air - throughout the storing period to make sure no heat build up inside. Without these careful ventilation steps, flowers wilt very quickly prior to scenting.

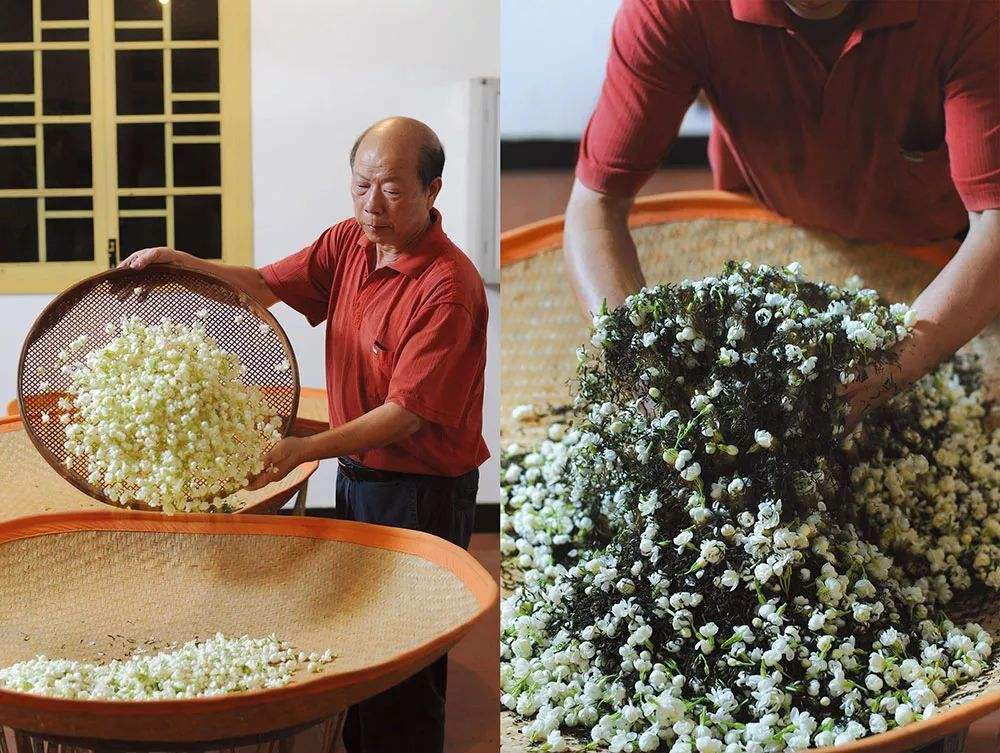

Sorting of flowers are completed using bamboo sieves - there are 13 different mesh sizes to choose from. Craftsmen rotate the sieve tray in a continuous motion to remove any unopened flowers, broken stems/leaves etc from optimum opened flowers. These sorting steps are done with much efficiency with minimum damage to the flowers, thus prolonging the lifetime of picked flowers.

Step 3: Weighing

Craftsmen then decide on the ratio of jasmine flowers to tea depending on the grade of jasmine tea desired - higher ratio of flower:tea, better the results (usually, but not always).

One way to 'test' the skill of a jasmine craftsman is to ask his/her loading ratio for a given jasmine tea made - more skilled craftsman can achieve lower loading, with better results.

(Photo: jasmine flowers laid out side by side with white tea, ready to be scented)

Step 4&5 : Scenting Yin Hua “窨花” and ventilation Tong Hua “通花”

Arguably the most important part: scenting - the key is to make sure two ingredients are mixed thoroughly together in an even distributed manner.

- this is easier said than done (!) -

Craftsmen use shovels to manually conduct the mixing in large scale, and for smaller batches mixed skilfully by hand on a flat bamboo basket.

(Photo: mixing of jasmine flowers with tea)

Because adsorption and transfer of jasmine oil to the tea emit heat, the mixed batch needs to be periodically lifted into air to ventilate keeping flowers alive - a process known as Tong Hua “通花”

Flowers cannot survive above 40°C, and this may sounds high, but in fact during the summer months in the south China region where most jasmine teas are made, it is relatively easy to exceed 40°C in the workshops even during the night.

The optimum transfer window is said to be somewhere between 38-40°C, so no A/C either.. ventilations are done through fans attached to the wall.

Even though this temperature range is narrow, but not a single skilled craftsmen we’ve seen monitor these temperatures using equipment. So, how do they do it?

(Photo: piled up jasmine flowers with tea during scenting process)

The craftsmen judge the condition and whether to increase ventilation or not, by simply observing the flowers’ state in the batch - a knowhow only taught from master to protege through years of practice.

Asked whether there is written rules on when to stop the process, the answers from these craftsmen have always been along the lines of “it depends on the batch and day”. This is not to keep anything secret.

It turns out, just like other crafted teas, there is no standardised process (of course, there shouldn’t be as each batch of harvested tea is unique..) and the optimum temperature regime suggested above is more of a ‘recent’ study to include it in the textbooks…

Step 6: Removal of flowers

At the end of each scenting cycle, flowers are separated from the tea using sieves. The scent absorbed tea now weighs heavier than before from the newly added oil/moisture.

Trivia: Why remove the flowers if the entire process is about transferring scent to tea? Now, you may have seen jasmine flowers in your cup of tea... Jasmine belongs to a type of flower that loses its aroma and essence oil after opening. The essence oil is gradually lost in the air as the flower opens, so the dried flower(s) in your cup has long lost its aroma, and is only there for visual aesthetic. In fact, high quality jasmine tea requires removal of these unwanted jasmine flowers after each scenting to preserve the taste of tea.

(Photo: removing jasmine flowers and re-scenting)

Step 7: Roasting

Removing the excess moisture of tea makes it shelf-stable for storage.

Scenting process is then repeated multiple times with fresh batch of jasmine flowers in every cycle.

One scenting cycle takes around ONE whole day. Obviously with more cycles, more time and laborious the process becomes…

One cannot be too complacent even with the last step. As it is often the case, over-roasting destroys the aroma irreparably so great care is taken by craftsmen to the very last step.

Step 8: Final scenting (optional)

Depending on the state of tea, the craftsmen may choose to add a final scenting step in which additional batch of flowers are mixed with roasted tea to give it an extra lift. After several hours, these flowers are removed and tea is left to dry naturally.

On average, newly made jasmine tea is slightly ‘wet’ in comparison to other non-scented teas - a reason why some jasmine teas are said to have shorter shelf lives.

Finally, there are some illustrative guides (again, not standardised) to the number of cycles for each grade of jasmine tea:

Normal grade 2-4 cycles

High grade 5-7 cycles

Special grade 8-9 cycles